PROCESSES

CNC MACHINING

CNC MACHINING

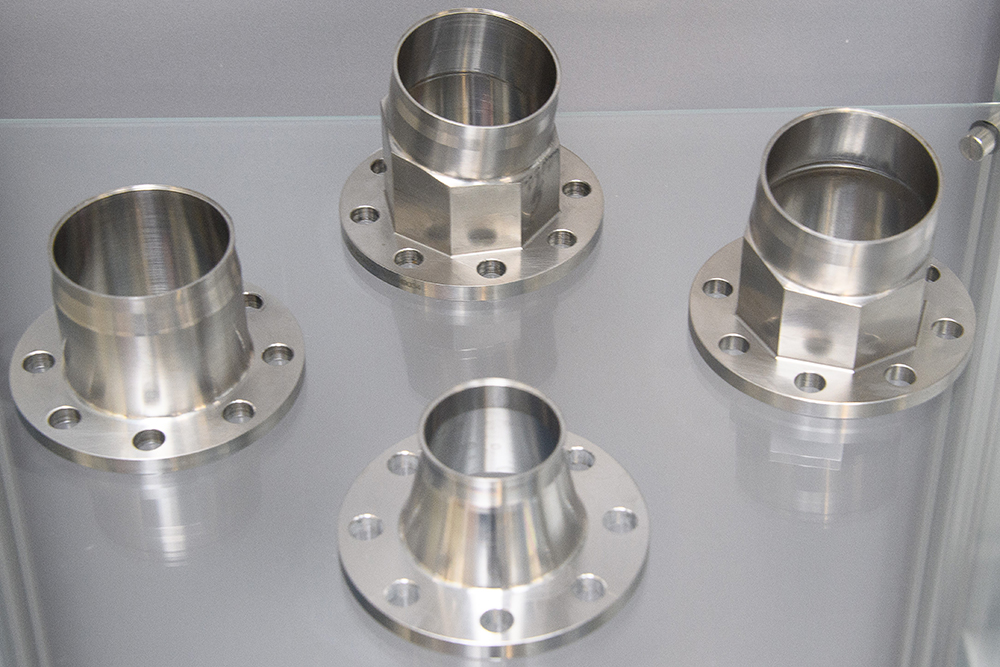

Accles & Pollock have transitioned from a tube bending and joining specialist with some machining capability to a full service provider with “state of the art” machining technology and skills. Engine development to increase fuel efficiency necessitates higher operating temperatures and we have invested in new equipment to machine hard materials such as Inconel alloys. Specialising in large and complex fittings, these components are incorporated into various tubular assemblies.

Our “fast make” capability allows us to react quickly to customer requirements.

Accles & Pollock have transitioned from a tube bending and joining specialist with some machining capability to a full service provider with “state of the art” machining technology and skills. Engine development to increase fuel efficiency necessitates higher operating temperatures and we have invested in new equipment to machine hard materials such as Inconel alloys. Specialising in large and complex fittings, these components are incorporated into various tubular assemblies.

Machining Capabilities include:

NLX2500 – Universal turning by DMG Mori

Twin Spindle Lathes with Live turret & milling capabilities.

INTEGREX i-200S 5 axis machining centres

Full 5-axis capability, processes round parts with secondary operations, fully prismatic and highly contoured parts from billets or bar.

CNC Turning centres

First stage cylindrical parts, increases process variation, short lead time

Vertical milling machines

Second stage machining, rapid material removal rates, short lead-time

Other resources

- Mechanised orbital TIG welding

- 5 X XYZ Machining centres